What is XCP?

In the world of automotive engineering and embedded systems, precision and control are extremely important. Whether it is fine-tuning engine performance, optimizing fuel efficiency, or ensuring the safety of advanced driver assistance systems – the ability to measure and calibrate components with accuracy is essential. This is where XCP comes into play.

XCP plays a critical role in enabling engineers and developers to improve the performance and functionality of their devices and systems. In this blog post, we will dive into the world of XCP and explore its origins, applications, and importance.

What is XCP?

XCP is a standardized network protocol and stands for Universal Measurement and Calibration Protocol, whereas the first letter X denotes that the protocol is designed for a variety of bus systems. The protocol provides a standardized communication interface between a calibration tool (typically a PC) and an embedded electronic control unit (ECU). XCP simplifies the process of accessing and adjusting parameters, allowing engineers to fine-tune and optimize the performance of ECUs.

XCP was originally established in 2003 by ASAM (Association for Standardization of Automation and Measuring Systems) to address the growing complexity of embedded systems in motor vehicles. As vehicles became more advanced and complex, engineers needed a more efficient way to calibrate and fine-tune these systems. The previously prevalent CAN calibration protocol (CCP) could not meet these challenges and XCP was introduced as a successful solution.

What are the benefits?

In comparison with others like its predecessor CCP, XCP provides several benefits. The key features are:

Efficiency

XCP is designed for high-speed data exchange, making it possible to read and write data to an ECU quickly. This is crucial when it is required to make real-time adjustments to an ECU’s parameters. Further, it offers a more precise data acquisition by measuring ECU timestamps and a higher data throughput.

Flexibility

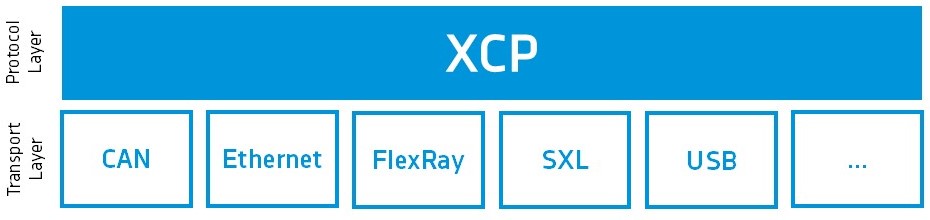

XCP is a two-layer protocol, meaning that it consistently separates the protocol and transport layer. This makes it particularly versatile because it can work with various transport layers by always using the same protocol layer. XCP supports synchronous and asynchronous serial interfaces which for instance include CAN (FD), Ethernet, FlexRay, SxL, and more. This makes XCP extremely multifarious and useful for various tasks, such as flashing new firmware, monitoring sensor data, and calibrating control parameters.

Security

XCP protocols often come with built-in security features, such as encryption and authentication, to protect sensitive data and prevent unauthorized access. This is especially important in today’s automotive industry, where cybersecurity is a growing concern.

Although XCP offers many advantages, CCP is still used. Especially in cases where legacy system compatibility and existing infrastructure are a concern, CCP has its raison d’être. However, as the automotive industry continues to evolve, XCP’s advantages in speed, efficiency, and versatility make it the preferred option for many modern vehicle calibration and measurement tasks.

Where is XCP applied?

As we already established multiple times, XCP is predominantly used in the automotive industry. It is a fundamental tool for calibrating and optimizing the performance of ECUs in vehicles. Additionally, it plays a vital role in the calibration of electric and hybrid vehicle systems. It allows for precise control of battery management, electric motor behavior, and energy consumption.

However, the automotive industry is not the only field of application. Its flexibility and versatile applicability make it a valuable tool for developers in other domains as well. In the aerospace industry, XCP is used to calibrate and fine-tune avionics systems and sensors. Furthermore, in the field of industrial automation, it assists automation systems, ensuring accurate and reliable operation.

OXYGEN’s XCP feature

In case you do not know it yet: OXYGEN is our intuitive data acquisition software. It is a versatile but easy-to-use measurement software that is used in a wide variety of fields. Besides measuring and recording data, OXYGEN enables:

- data analysis and post-processing

- power and efficiency analysis

- sound level analysis

- order analysis

- system monitoring

- and much much more

As it may be used for so many different applications, OXYGEN also supports multiple network protocols and transport interfaces, including CAN, FlexRay, EtherCAT, XCP, and more. So, in case you require XCP for your test bench, simply select our optional XCP software option. This allows the OXYGEN software to act as an XCP slave and deliver measurement data to your system.