What is WLTP? – Worldwide Harmonized Light-Duty Vehicles Test Procedure

In the dynamic realm of automotive technology and environmental consciousness, the need for standardized testing procedures has never been as important as it is today. The introduction of the WLTP was a major step forward in this respect. Today, we will have a closer look at this test procedure and its history.

What is WLTP?

WLTP stands for Worldwide Harmonized Light-Duty Vehicles Test Procedure and was initially published by the United Nations Economic Commission for Europe (UNECE) in 2014. As the name implies, it is a globally standardized test procedure for motor vehicles, including combustion engines, hybrid (NOVC-HEV and OVC-HEV) and pure electric vehicles. The original proposal describes its aims as follows:

“This global technical regulation (gtr) aims at providing a worldwide harmonized method to determine the levels of gaseous, particulate matter, particle number, CO2 emissions, fuel consumption, electric energy consumption and electric range from light-duty vehicles in a repeatable and reproducible manner designed to be representative of real world vehicle operation.”

Put simply, the WLTP provides a more accurate representation of a vehicle’s fuel consumption and emissions under real-world driving conditions.

The history of WLTP

To record and monitor the emission levels of cars, a standardized test procedure was introduced in the 1970s. It is known as the New European Driving Cycle (NEDC). However, due to the rapid evolution in the automotive industry, the NEDC struggled to keep pace with these changes. This led to large discrepancies between the results of the laboratory tests and real-world driving conditions. The need for a more comprehensive, realistic, and globally applicable testing standard became evident. This resulted in the development and introduction of the WLTP. Especially after the emissions scandal in 2015, it became clear how important it is to have reliable and accurate emissions tests. This also pushed the adaption of the WLTP worldwide. Nowadays, the WLTP is well implemented in the majority of European countries, the United States, China, Japan, and many more.

Test procedure & driving cycles

The total test procedure defines numerous conditions, including gear changes, total vehicle mass (including additional equipment, freight and passengers), fuel quality, ambient temperature and tire selection and pressure. One key aspect of the procedure is the different test cycles also called WLTCs. There are three different test cycles, which depend on the vehicle class and are defined by the power/weight ratio PWr in W/kg. They are as follows:

- Class 1 – low power vehicles with PWr ≤ 22

- Class 2 – vehicles with 22 < PWr ≤ 34

- Class 3 – high-power vehicles with PWr > 34

For class 3, further division is possible depending on the vehicle’s maximum driving speed: class 3a for vehicles with max. speed < 120 km/h, and class 3b for vehicles with max. speed ≥ 120 km/h.

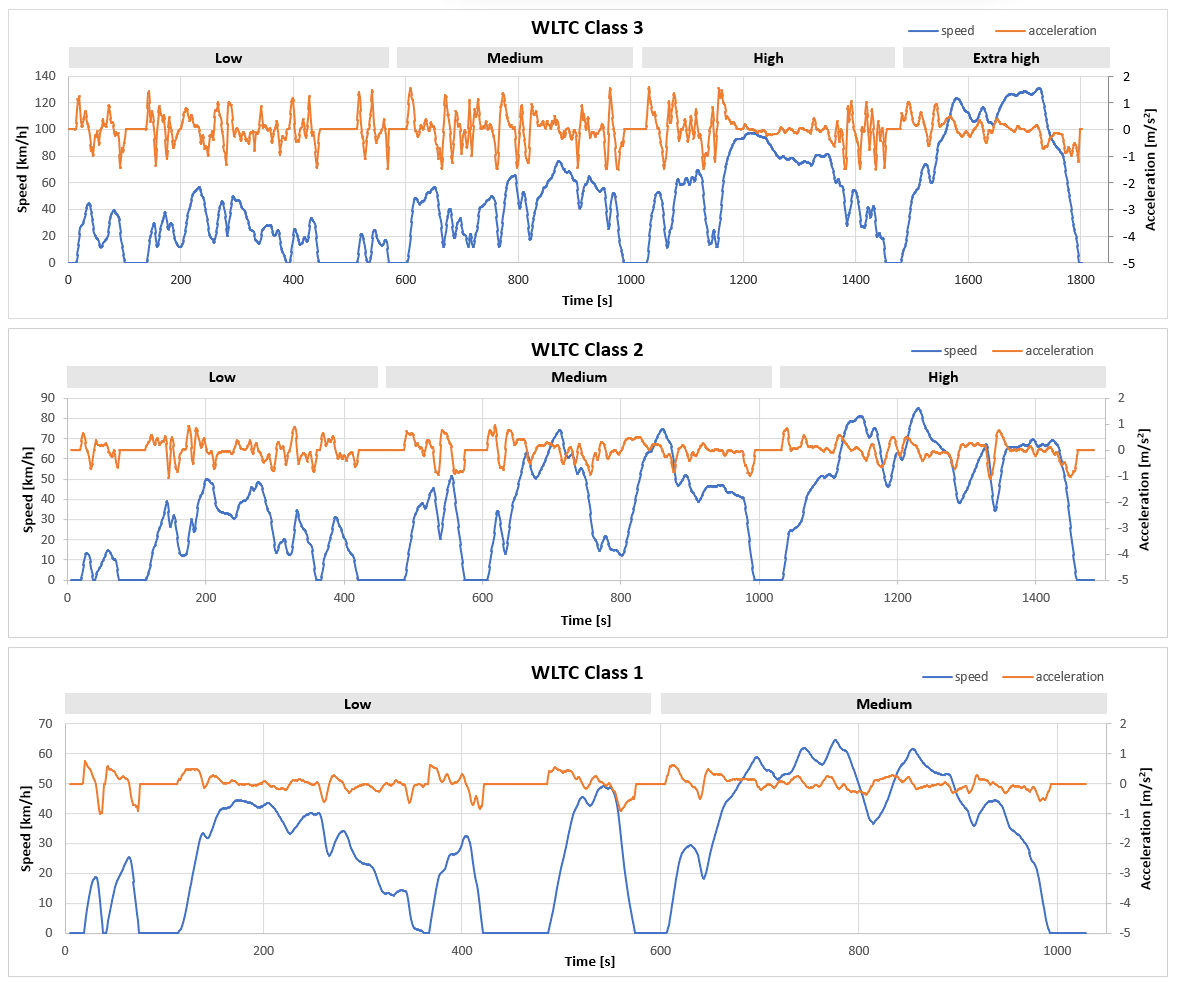

The duration of a test, as well as the acceleration and speed curves, vary and depend on the vehicle class. Furthermore, there are additional restrictions due to the maximum vehicle speed. See Fig. 1 for class-dependent acceleration and speed curves.

Fig. 1 WLTC drive cycle diagrams for vehicles of all three classes.

Each drive cycle is further divided into multiple sub-parts, which are defined according to their maximum speed. These drive cycles exist for each class to reflect vehicle operation on various roads (urban, suburban, motorways, highways, …) under diverging conditions.

A further key aspect of the WLTP is the repeatability and reproducibility of the tests. Which is important in order to ensure comparability for all vehicles from different car manufacturers.

What are the benefits of WLTP?

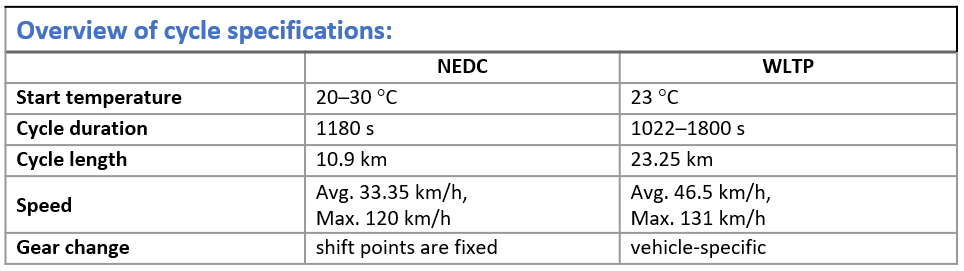

In the following paragraph, we show the improvements of the test procedure compared to its predecessor, the NEDC, based on 3 key features.

1. Realistic driving conditions:

In comparison to the NEDC, the WLTP considers a wider range of driving scenarios, including high speeds, aggressive acceleration, and various driving styles. This ensures that test results are more consistent with real-world driving conditions, giving consumers a better understanding of a vehicle’s performance.

2. Extended testing duration:

The new test procedure extends the testing duration to approx. 30 minutes, covering around 23 kilometers. This enables a more accurate assessment of a vehicle’s efficiency and emissions profile and covers a wider range of driving conditions.

3. Stricter testing parameters:

The WLTP implements tighter tolerances and stricter testing parameters. First, this helps to minimize the gap between laboratory results and real-world performance. Further, it improves the reliability and comparability of the test results between different vehicle models and manufacturers.

DEWETRON’s DAQ systems for all scenarios

As already established, the WLTP aims to minimize the discrepancies between laboratory results and results under real-world driving conditions. Consequently, various types of tests and test locations are required.

It is exactly for such scenarios that we at DEWETRON offer modular DAQ systems for a wide range of applications. On one hand, we provide you with easily customizable but rugged mainframe systems for stationary tests at test benches. Such systems offer up to analog inputs which makes them perfect for numerous simultaneous measurements.

On the other hand, our portable all-in-one systems are the perfect solution for on-road tests under real-world conditions. They are also fully modular and have a built-in display for quick analysis. Therefore, they are our convenient and compact solution for mobile applications.

In case you are only looking for a front-end system we offer the NEX[DAQ]. This handy and robust DAQ-system with 8 analog inputs. In combination with an MSI2-V-600 and current clamps, it is the ideal solution for driving range tests.

| Mainframe systems | All-in-one | NEXDAQ |

Summary

The WLTP is a globally standardized test procedure for determining the levels of pollutants, CO2 emissions and fuel consumption of cars. It is the successor of the NEDC and is required to

- accurately inform customers about the emissions and fuel consumption of their vehicles,

- and to improve the overall environmental performance of vehicles.

The test procedure is divided into three classes depending on the vehicle class defined by the power/weight ratio PWr. Each class considers various driving scenarios to evaluate different driving styles for reliable and comparable test results.