High-precision power analyzer for engine test benches

What is the customer’s measurement task?

The customer is an internationally active automotive supplier for entire (electric) drive systems and develops future powertrain technologies and related accessories. This includes intensive research and development in the fields of combustion and electrification as well as topics even beyond powertrains. Therefore, the customer needs a measurement system that provides data for further development steps, optimization, and verification. Above all, having a single measurement system for a variety of applications as well as diverse engine and motor types is essential for the customer. Hence, the goal of this project was to define one measurement system that fulfills the requirements of all measurement tasks.

Which configuration provided the right system?

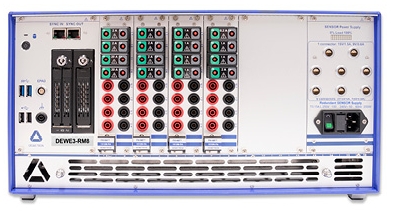

The customer’s chassis is a DEWE3-PA8-RM which offers space for up to eight TRION/TRION3 modules and integrated redundant 8-fold supply for current transducers. The right configuration for the customer’s application includes the following modules:

- 2 x TRION3-1810M-POWER-4 (each with four 1 A sub-modules) to measure performance values

- 1 x TRION3-1850-MULTI for various parameters such as vibration, low voltage, or strain

- 1 x TRION-BASE to acquire frequency signals such as torque and rotational speed with measuring shafts

- 1 x TRION-CAN to measure CAN parameters of the DUT on the one hand and to write measured values on the customer’s automation CAN bus on the other hand

In addition to that, the system comprises three EPAD2-TH8 type K (static channel expansion directly connected to the chassis) to continuously acquire the raw data of a total of 24 thermocouples and eight PA-IN-1000-S current transducers (latest generation by LEM). Moreover, the customer takes advantage of the basic license of our measurement software OXYGEN complemented with a plurality of further OXYGEN options such as:

- OPT-POWER-BASIC and OPT-POWER-ADV to perform power analysis with the automatic calculation of various power parameters

- OPT-CAN-OUT to send data over CAN

- OPT-XCP-OUT to use the XCP protocol

Which signals/physical units does the customer want to measure?

The customer conducts analyses in the high voltage range which is why high isolation is a requirement. Based on these preceding analyses, further electrical quantities such as active, reactive, and apparent power, harmonics, and others are calculated. By adding mechanical parameters such as torque and rotational speed the customer receives an all-encompassing view. Like that, the customer analyzes the efficiency of the entire system starting from the battery over the inverter motor up to the wheels. In addition to that, the customer acquires physical units such as temperature, low voltage, vibration, strain, thermoelements, and CAN data. Moreover, the system provides previously acquired data for the customer’s automation CAN bus.

Why was OXYGEN the right choice? Does the customer use additional software options?

OXYGEN represents the ideal solution as it covers the entire scope of the customer’s measurement requirements. This includes for instance the scaling of signals, continuous raw data acquisition, high-performance online power calculation, and the test bench interface. Moreover, the customer uses CAN for the automation as well as XCP over Ethernet for online data transfer to third-party tools.

Next to our standard OXYGEN license, the customer uses the additional options OPT-POWER-BASIC, OPT-POWER-ADV, OPT-CAN-OUT, and OPT-XCP-OUT.

How does further data processing look like?

The customer uses the online as well as the offline analysis function of OXYGEN to analyze the vast amount of collected data. The processing of parameters relevant for the test bench takes place online. If a DUT fails, the simultaneously stored raw data allows performing further analyses offline.

Where does the customer want to use the system?

The customer is seeking a typical test bench application. Therefore, the DEWETRON system will find a stationary application. As a result, the customer does not need a built-in display and the size of the chassis is rather insignificant. However, long-term stability, performance, and – above all – accuracy are highly important.

How does the customer want to access the system?

OXYGEN not only offers various possibilities for data transfer but also for remote control. As RDP (Windows Remote Desktop Protocol) is a simple solution that works with every Windows-based system, this provides the right solution for the customer to fully access and control the system.

Which sampling rate does the customer need?

The sampling rate is subject to variation and heavily depends on the application. While the sampling rate is rather low for battery or endurance tests, the customer exploits the entire 10 MHz range for efficiency as well as optimization measurements.

What about the bandwidth?

Similar to the sampling rate, the bandwidth depends on the application as well. For continuous monitoring, the customer only needs a low bandwidth. However, when conducting a performance test, the customer takes advantage of every detail provided by the 5 MHz bandwidth. Therefore, DEWETRON equips its systems with a full bandwidth range to enable a universal application.

Does the application require sensor power supply?

Yes, the customer works with eight current transducers which need an external power supply. DEWETRON’s DEWE3-PA8-RM offers integrated redundant 8-fold supply for current transducers, yet the customer initially worked with the product of a third-party supplier. After some time, however, the customer decided to switch to DEWETRON’s solution for quality reasons. Moreover, the already integrated power supply proved useful and space-saving.

Why did the customer choose DEWETRON equipment over other products?

The customer appreciates the versatility of the equipment, which is not at odds with performance and accuracy. Over time, the customer developed increasing importance for poly-phase measurements of drivetrains. At the moment, the customer performs analyses with eight phases. Nevertheless, considering future challenges, the simplicity and speed with which you can expand the system to even more phases allow fast scalability.

In course of the time, a true partnership developed and promises long-term cooperation. Until now, DEWETRON supplied more than 20 power analyzers for sites in Germany, France, Romania, and China. Moreover, the customer appreciates receiving everything from one single source. Like that, DEWETRON for instance regularly calibrates all systems according to ISO 17025 and bridges the guaranteed turnaround time with spare devices to prevent downtimes.

Meet our expert to talk about this application

Sven Deckert – Senior Sales Manager at DEWETRON – guided the customer through the entire project with advice and assistance. He is very passionate about challenges in the mobility sector no matter whether four, two, or even no tires. Click here to connect with him on LinkedIn.

EMAIL: [email protected]

PHONE: +49 7181 2698111