Revolutionizing construction vehicle testing with NEX[DAQ]

Construction vehicles, heavy equipment, machines for earth moving or off-highway vehicles encompassing a wide range of machinery from excavators, crane to bulldozers, operate in some of the harshest environments. These vehicles face challenges that demand robust, accurate, and versatile data acquisition systems. In response, the NEX[DAQ] is our optimal solution to meet the rigorous demands of heavy machinery testing.

In this blog post, we have a look at construction vehicles, how they are categorized, and some typical examples. Further, we describe how our portable, yet powerful NEX[DAQ] can be of use and help in testing heavy equipment vehicles.

What are construction vehicles?

Construction vehicles represent a broad category of vehicles that are specifically designed to operate on rough, unpaved surfaces. Even though many heavy equipment are allowed to be driven on a public road, they are primarily designed for different applications. Off-highway vehicles (OHV) are used in various industries, including construction, mining, agriculture, forestry, etc. Typical examples of such vehicles include:

| > Excavators or electric excavator | > Tractors | > Drills | > Skidders | > Cranes |

| > Bulldozers or Dozers | > Harvesters | > Dump trucks | > Wheel loaders | > Truck vehicles |

However, not all OHVs need to be of the type of heavy machinery. There exist further subgroups of smaller off-road vehicles that are not only used for industrial purposes. The exact definition of which vehicles are part of which subgroup can vary from country to country. However, they are usually categorized as follows:

All-Terrain Vehicles (ATVs) are three or four-wheel vehicles with low-pressure tires for off-road applications commonly designed for a single operator, e.g. Quadbikes.

Utility Task Vehicles (UTVs) are four-wheeled or multi-wheeled vehicles designed to transport several people. Commonly they have maximum speeds of 50 km/h or less and are often also used for non-industrial applications, like sightseeing in rough rural regions.

Recreational Off-Highway Vehicles (ROVs) are similar to UTVs but can reach speeds way above 50 km/h and are most often designed for one to four people. Examples are all kinds of off-road buggies used in motorsports.

Fig. 1: Examples for OHVs

What is the NEX[DAQ]?

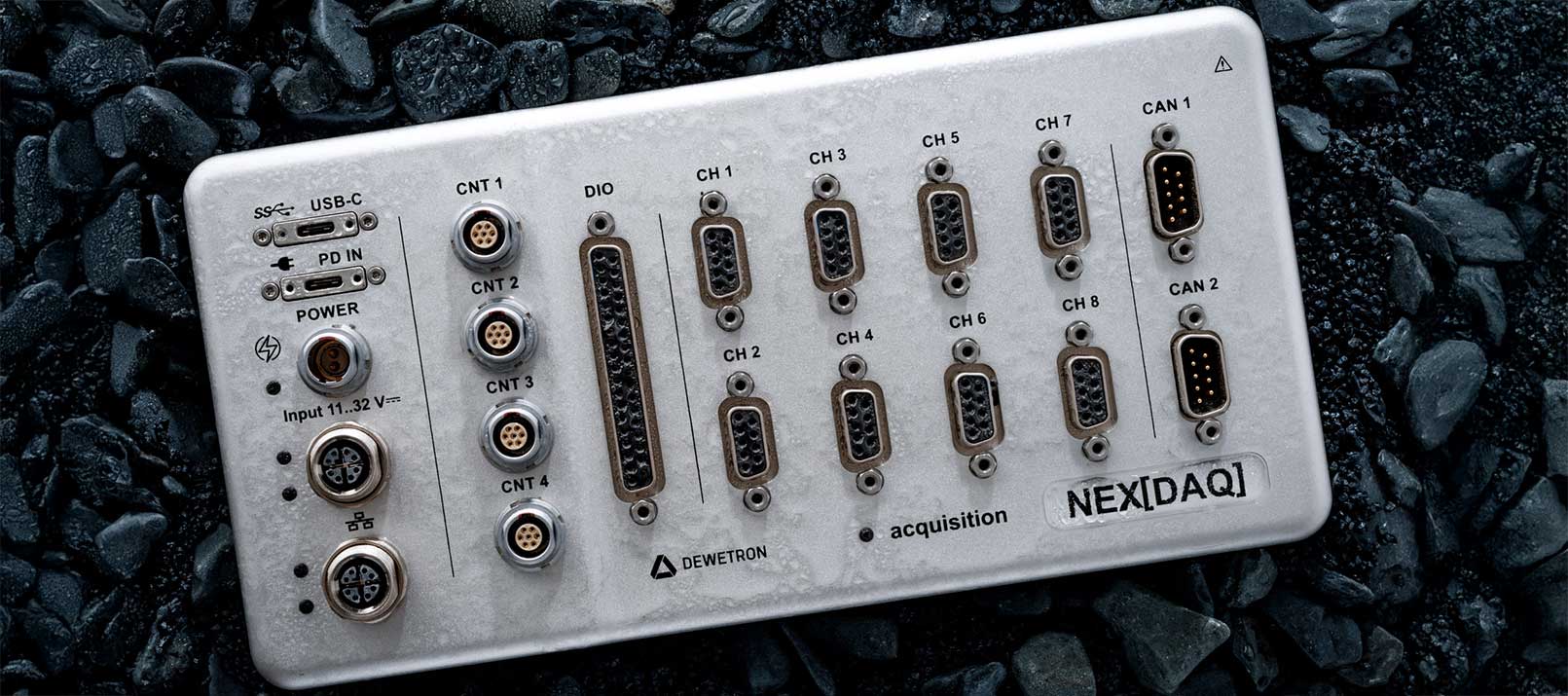

The NEX[DAQ] is an advanced, yet compact Data Acquisition (DAQ) system tailored for harsh operational conditions, making it ideal for OHVs and the challenges posed by their environment. It offers extensive capabilities for internal combustion engines (ICE), electric motors, powertrains, and power electronics, ensuring comprehensive testing and monitoring for both traditional and electrified vehicles. This versatile DAQ system is perfect for identifying the root cause of problems. Especially when multiple sensors are required, such as accelerometers, microphones, speed and angle sensors.

Five key features and benefits

- The NEX[DAQ] system boasts an IP67 rating, ensuring it is completely dust-tight and protected against temporary immersion in water.

- It operates effectively in extreme environments, with a temperature range from -20 °C to +70 °C.

- Power supply options for the NEX[DAQ] are versatile, including Power-over-Ethernet, USB-C, vehicle supply, or a power bank.

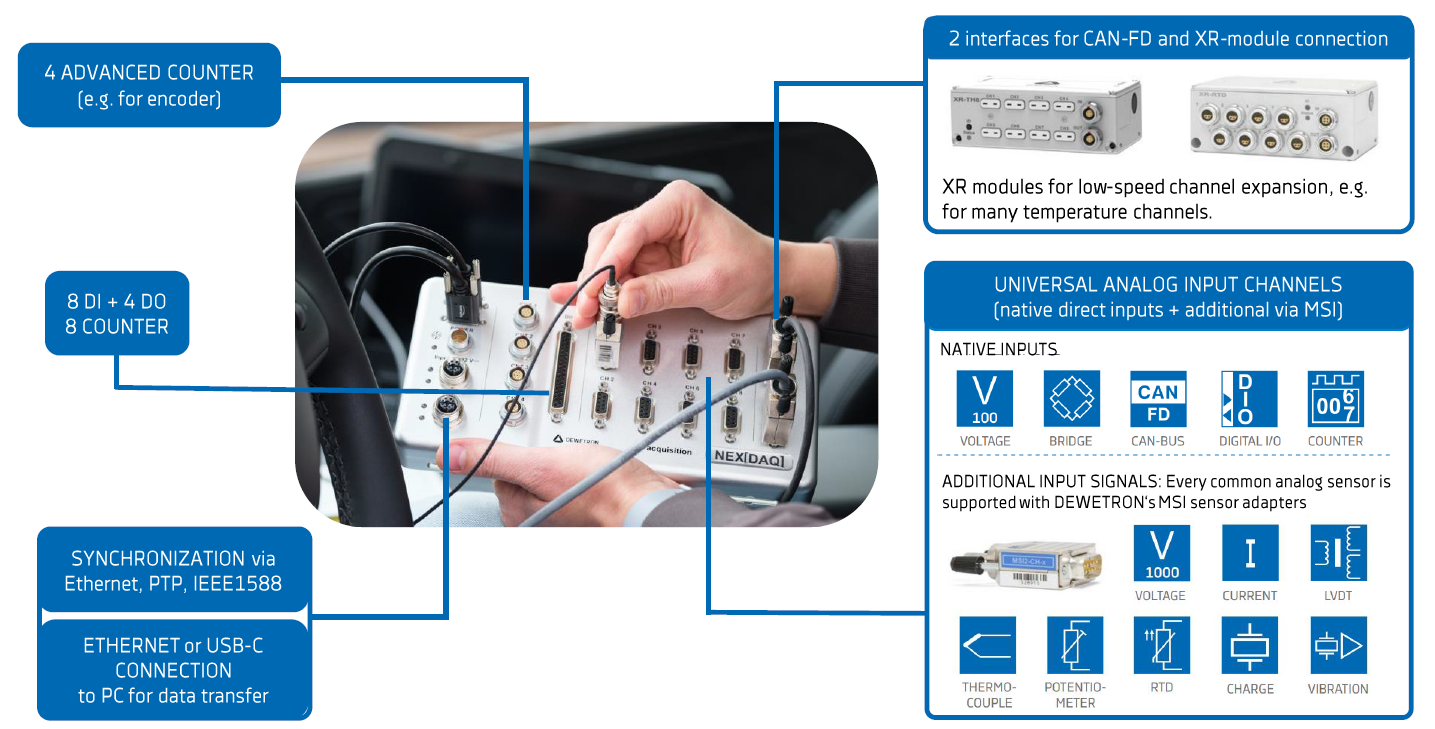

- The system provides multiple connection options for measuring devices and sensors, featuring 8 analog input channels, 2 interfaces for CAN-FD or XR-modules, 4 advanced counter inputs, and a DIO connector with 8 digital inputs, 4 digital outputs, and 8 auxiliary counter pins.

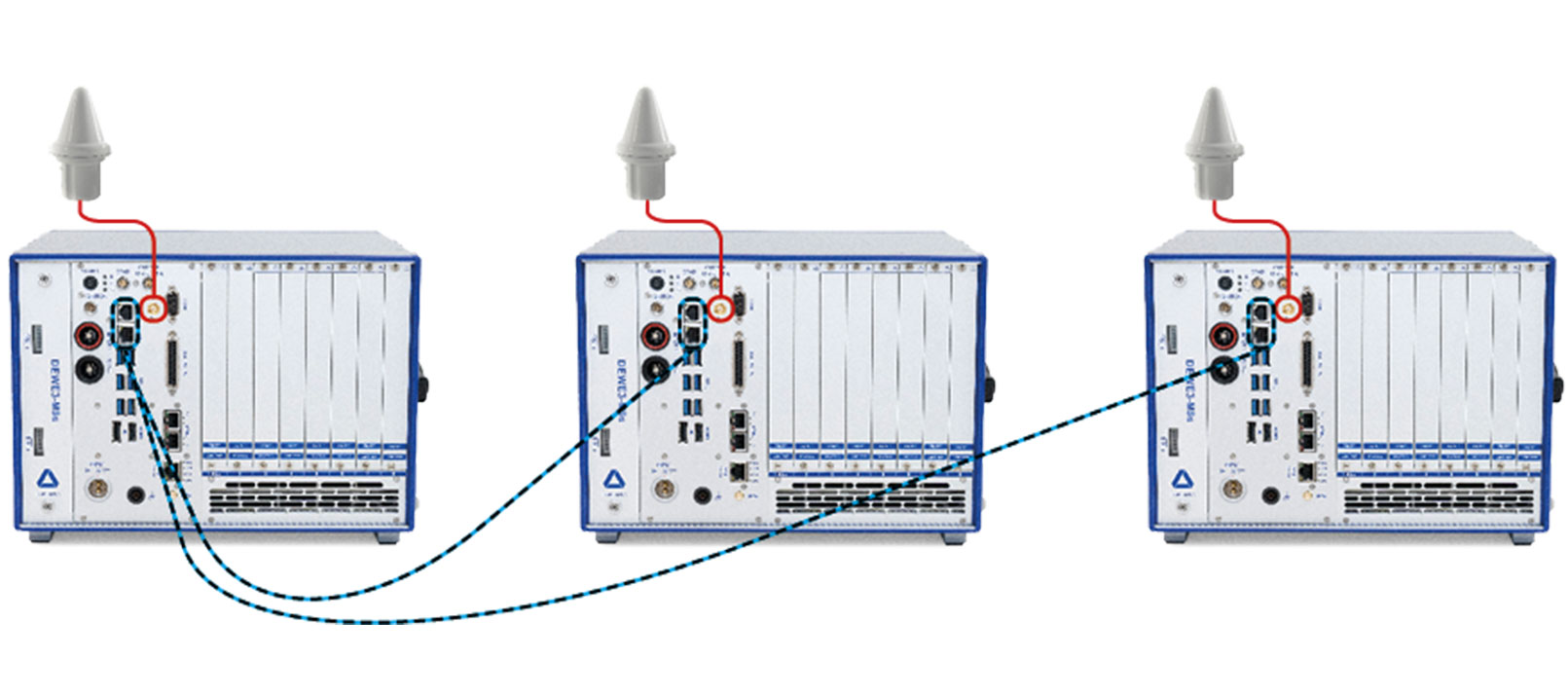

- Together with our measurement software OXYGEN, the NEX[DAQ] ensures quick and easy, but comprehensive data recording and analysis.

Fig. 2: NEX[DAQ]’s available interfaces

NEX[DAQ] applications for Construction vehicles

The NEX[DAQ] is the ideal system to determine the cause of problems or to monitor the behavior of components, especially when multiple sensors are required. In the following, we present some practical application examples in the field of off-highway heavy machinery and explain how the NEX[DAQ] can be of help:

Power monitoring

The NEX[DAQ] together with an MSI2-V-600 and current clamps is the ideal solution for in-field power measurements on the generator of the DUT. It can simultaneously monitor signals on the DUT’s communication bus as a reference.

Component tests

The NEX[DAQ] is capable of measuring strain, force, and load on an excavator arm, as well as pressure at various points in a hydraulic circuit simultaneously. Its rugged design allows it to be mounted externally, close to the measurement position.

Simple NVH tests

Microphones and accelerometers can be connected to the NEX[DAQ] for air- and structure-borne noise tests. Its fanless design allows it to be placed close to the DUT, minimizing cable lengths and ensuring accurate measurements.

Field tests

Tests on excavators, bulldozers, or other heavy machinery require a robust and compact DAQ system with multiple analog and digital inputs as well as counter channels. The NEX[DAQ] offers all these functions together with versatile mounting options.

Thermal management tests

In combination with XR modules, the NEXDAQ is ideal for thermal management tests, and temperature monitoring in the cooling circuit or during electrical power analysis.

Praxis example: excavator testing

Integrated sensors

Readout of vehicle-integrated sensors either via CAN, CAN-FD or J1939.

Passenger compartment

Strong vibrations and noise are caused by heavy-duty machines that can affect the driver. The vibration and noise inside the driver‘s cabin can be measured to ensure that labor regulations are fulfilled, and the driver is not harmed.

ICE, electric motor, powertrain & power electronics

Conduct NVH assessments, efficiency tests, and temperature measurements. Monitor water temperature, electrical and mechanical power in BEV (Battery Electric Vehicles) and HEV (Hybrid Electric Vehicles), as well as speed, rotation, and acceleration.

Drive train & road contact

Perform force measurements on the driver shafts, and measure wheel forces, pressure, and torques under various driving conditions.

Electrified vehicles

Perform comprehensive battery and charging tests for electric vehicles like electric excavators. E.g. battery cell characterization, charge-discharge cycles, life tests, state of health assessments, charging infrastructure analysis, power analysis, etc.

Fig. 3: Potential applications for measuring or monitoring components at different measuring points of an excavator

Conclusion

The NEX[DAQ] is not just a data acquisition system, but a comprehensive solution for the challenging requirements of heavy equipment vehicle testing. Its precision, durability, and advanced features make it an indispensable tool to ensure the efficiency, reliability, and safety of heavy machinery. Whether you are performing thermal management testing, NVH analysis, or performance monitoring, the NEX[DAQ] provides all data and insights required to monitor and analyze your vehicle.