Wind Turbine Economics - Calculator

Whether onshore, or offshore, all wind farm operators face extensive technical, logistical and economic challenges. Achieving a difference of just 1 % in the overall performance can make a decisive difference between profit or loss and success or failure. Unquestionably, the economics are tough! Read on to find out how much potential still remains untapped.

A Wind Turbine In Numbers

The maximum capacity to produce electric power are 2 MW for commonly used wind turbines.

An average 2 MW wind turbine costs $ 3,500,000.00 (installation and commissioning included).

Wind turbines have an expected lifetime of approximately 20 years.

Load Factor Benchmarks

Wind turbines have an expected lifetime of approximately 20 years. On average, a wind turbine pays for itself within 10 to 15 years. However, how long it really takes depends largely on how much of its theoretical capacity is actually being exploited; this is commonly known as the load factor. More than any other input, load factors drive the economics of wind energy production.

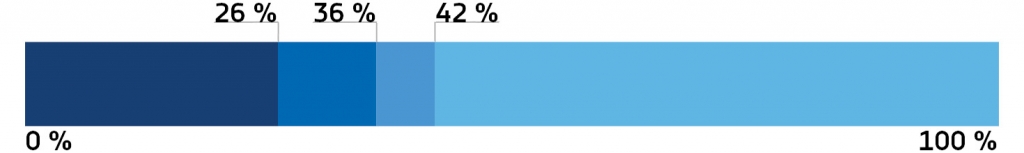

On modern wind turbines, average load factors range between 26 % at the low end and 52 % at the high end. However, a realistic benchmark for a good average load factor is 42 % on a single wind turbine, or 36 % as a fleet average.

The Calculation

The following calculation considers a wind turbine rated at 2 MW and a feed-in tariff of 9 cents per kWh (current pricing in Austin, Texas over a period of 10 years):

| LOAD FACTOR | ELECTRIC ENERGY / YEAR | REVENUES / YEAR |

|---|---|---|

| Good average load factor of 42 % | 7,358 MWh (∼ 7,358,400 kWh) | $ 662,256.00 |

| Low end average load factor 26 % | 4,555 MWh (∼ 4,555,200 kWh) | $ 409,968.00 |

| POTENTIAL LOSS / YEAR | 2,803 MWh (∼ 2,803,200 kWh) | $ 252,288.00 |

The Cost of Load Factor Underperformance

The total revenue loss over the average lifetime of a wind turbine (20 years) is stunning. It amounts to $ 5,045,760.00 on a 2 MW wind turbine. Achieving even a one point load factor improvement would result in a net gain of $ 315,360.00 on just one 2 MW wind turbine.

Some more notable facts

Insights into failures

Insights into failures

According to the insurer, German Lloyd, the likely sources of wind turbine failure are the main gearbox* (32 %), the generator (23 %), the main bearing (11 %) and the rotor blades due to resonances and excessive vibration (less than 10 %).

*Delivery times on a new gearbox can take up to six months.

Downtimes in numbers

Downtimes in numbers

Downtime on 2 MW wind turbine, which normally runs at a 42 % load factor (a good, but reasonable benchmark) will cost an operator $ 1,814,40 per day in lost energy production, plus the cost of replacement parts, maintenance fees, shipping and misc. costs, etc.

The key to success

The key to success

Robust condition monitoring is the key to controlling the economics in your favor.

For condition monitoring systems, “good enough, isn’t,” – not even close!

Condition Monitoring System – CMS

At a minimum, any robust condition monitoring system should generate measurable results in the following areas:

- Achieving the highest load factors and fleet efficiency possible.

- Significantly reducing breakdowns and downtime.

- Significantly lowering annual O&M costs.

- Significantly lengthening wind turbine service lifetimes.

- Achieving a significant reduction in age-related performance degradation.

To predictably achieve these results, a modern condition monitoring system must fulfill some minimum requirements.

CMS Minimum Requirements

RELIABILITY

A highly reliable early warning system for all systems and subsystems, but especially for gearboxes, generators, main bearings and rotor blades. These components breakdown most often. They cost the most to repair or replace and they cause the longest downtimes.

SYNCHRONIZATION & DISTRIBUTION

A proven distributed measurement system, synched up through GPS, which generates a precision time protocol (PTP), needed for synchronization between linked CMS Systems (i.e. generator and transmission station). Locally distributed, synchronized measurements keep cable lengths short, avoid EMC problems, reduce visits and stop unnecessary climbing, etc.

MIXED SIGNAL CAPABILITY

Able to process mixed signals synchronously and save them in a single file. A robust CMS should be expandable at any time, convenient and easily adaptable to changing requirements. Learning curves should be short, troubleshooting easy and intuitive and analyses should be possible in real time or offline, after measurements have been taken.

RAW DATA STORAGE

Able to continuously store raw data, including voltages, currents and mechanical parameters. In fact, speed, torque, vibration and sound should all be continuously stored, synchronously, because this will cut out all the guesswork and allow operators to draw conclusions about the absolute rotor position at any time, to detect speed fluctuations within one revolution and to carry out a torsional vibration analysis, etc.

FLEXIBILITY

Highly flexible, allowing for a high number of inputs, taking advantage of RPM sensors, modular design, allowing for maximum test bench integration (at a minimum SCPI, XCP, EtherCAT and CAN), enabling offline set up and data analysis, etc.

O&M COST REDUCTION

Able to significantly reduce miscellaneous costs such as human error, skilled labor costs, service calls, spare parts, administrative and operational tasks, troubleshooting, traveling to and from the wind farm, climbing time and danger, inclement weather limitations, etc.

Keep Your Current Setup

Enjoy minimum disruption, because you can keep most (perhaps all) of what you already have. Integration is easy integration. Learning curves are short. Operation is intuitive:

DEWETRON solutions are quick, convenient, clean and headache free.

Avoid missing out on revenues that should be yours. The numbers are stunning. Achieving just a 1 % improvement will make a tremendous positive difference in your wind farm’s economics. See calculator or request a personalized report.

Avoid the costly breakdowns and downtime that destroy your ROI. Robust condition monitoring is the key to success.